Checkweighing with unparalleled simplicity and best-in-class precision is possible with the AD-4961. The A&D Inspection series checkweigher has a newly developed digital load cell with precise checkweighing within 0.08 grams. This level of precision minimizes the giveaway of materials above the specified weight, while also maintaining a high maximum speed of 320 pieces per minute. The AD-4961 utilizes a modular, IP65 stainless steel design for an entire system washdown, and its seven-inch color touchscreen provides a graphic user-friendly interface for easy system operation.

The modular system is designed to turn a conventional conveyor into an in-motion weighing system, adding functionality without adding additional space. This industrial scale system is made up of the Weigh Leg frame, which incorporates the weight sensors, a weight indicator, a photo eye kit (necessary for in motion weighing) and conveyor sections. When installed, the conveyor scale adds accurate and reliable weighing to new or existing production lines. The conveyor scale is suitable for checkweighing, conventional weighing and weight accumulation operations. Each system is custom designed for the specific application and available in either carbon or stainless steel. This then ensures the scale fits perfectly into your operation. These conveyor scales are legal for trade, making them suitable for commercial applications where product is sold by weight.

Cardinal Scale’s CIM series in-motion checkweigher offers a unique answer for in-motion weighing that will benefit any industrial and manufacturing production line. The CIM can greatly enhance quality control, part productivity, improve throughput, and reduce costly labor when weighing products quickly and efficiently on a conveyor-fed production line. This welcome addition to any conveyor line accurately detects products entering and exiting the conveyor scale, can classify products according to weight or mode, and can be easily customized according to hardware and software needs. Accumulators set through the Cardinal Scale weight indicator can keep track of product weights and counts, reset the counters if another product is selected, or keep an accurate product database for product reporting. If additional options are needed for quality control, a tower light with a buzzer can be attached, or rejector arms can be added to direct products that don’t meet preset weights off of the conveyor. Cardinal Scale’s in-motion checkweighers are perfect to weigh packages, parts, and food products in high volumes with speed and accuracy.

Rice Lake’s CW-90 checkweigher is designed to help speed up your weighing process and reduce production downtime, two critical factors to your company’s bottom line. Ease of use, real-time data collection, and rugged stainless steel construction make the CW-90 the equipment of choice for operators, quality control and maintenance departments. The CW-90 is competitively priced for all light industrial settings. The configuration menu of the CW-90 is accessible through the front keypad, eliminating the need to open the back of the indicator and expose the unit to moisture or contaminants. Access to these keypad controls can be limited to meet the operator’s needs. The CW-90 will store detailed information for up to 50 separate IDs, allowing for easy recall of previously saved information. An adjustable contrast display is visible in any environment. The CW-90 has kept things simple to meet the needs of today’s lean manufacturers. Use this checkweigher by easily watching the over/under lights. Program the unit with specified weight limits and a red light will display an underweight condition, yellow for over, and green when a target weight is reached. Rice Lake’s CW-90 will help error-proof your production process and achieve your productivity goals.

For heavy washdown environments and HACCP requirements, choose Rice Lake's CW-90X checkweigher. The CW-90X features the toughest keypad available. This rigid piezo device is made to withstand sharp knife-point contacts, and is resistant to most contaminants and liquids. The configuration menu of the CW-90X is accessible through the front keypad, eliminating the need to open the back of the indicator and expose the unit to moisture or contaminants. Access to these keypad controls can be limited to meet the operator's needs. The CW-90X will store detailed information for up to 50 separate IDs (expandable with WeighVault), allowing for easy recall of previously saved information. An adjustable contrast display is visible in any environment.

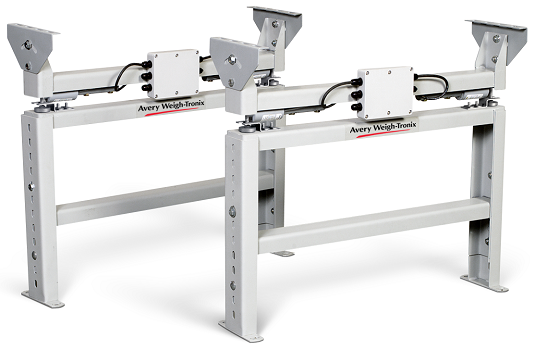

Rice Lake Weighing Systems’ ELS Series elevated load cell stands are made to replace existing legs on a conveyor to convert it into a scale. ELS Series weigh stands are a low-cost, flexible solution for all of your conveyor weighing needs. The weigh stands can be integrated into any pre-existing system to fit the exact height and width of your conveyor. This simplistic design is adaptable to a wide range of conveyor manufacturers. Rice Lake's ELS Series weigh stands are made of powder-coated mild steel that is built strong and flexible to fit a variety of weighing needs. The 2-part ELS Series weigh stands are available in 250-, 500- and a 1,000-pound capacity. The ELS Series is designed for its ease of installation and flexibility. The height and width are fully adjustable to fit your facility. With jack bolts and shims on the leveling feet, you can easily match your existing conveyor height.