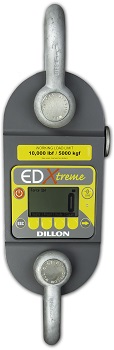

The EDXtreme exemplifies the trademark precision and rugged construction of Dillon dynamometers. Its highly refined design draws on the inherent strengths of premium-grade materials to achieve a 5:1 minimum factor of safety.* While the EDXtreme may be configured for something as simple as a digital hanging scale, it offers a higher level of intelligence. With user-defined functions and sophisticated communication options, the EDXtreme readily adapts to multi-tasking operations or multi-link systems capable of monitoring a series of critical stress points from a single location — it is the definition of application versatility.

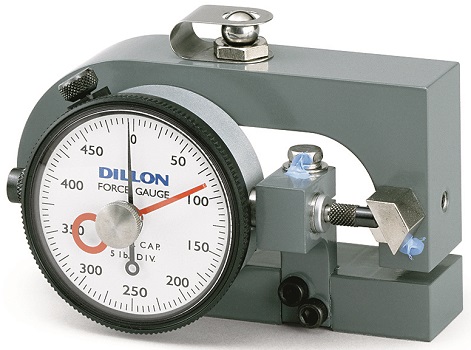

Model X-C comes in nine capacities ranging from 50 lb to 25,000 lb or 50 to 10,000 kg. All feature accuracy of ±1% of full capacity, except the 25,000 (10,000 kg) capacity instruments which are accurate to ±2% of full capacity. Load is applied against a hardened ball which rotates to maintain vertical alignment as pressure increases. The ball is held in place with a spring clip or retainer. A threaded mounting hole is located opposite the loading ball in the bottom of the beam. Model X-C is available in pound and kilogram capacities.

Force gauges calibrated in push-pull are available in four capacities in pounds ranging from 50-0-50 lb up to and including 2,500-0-2,500 lb and three metric capacities from 50-0-50 to 1,000-0-1,000 kg. Accuracy is ±2% of maximum dial reading (based upon total capacity of both compression and tension scales). Model X-PP gauges in capacities up to and including 500-0-500 lb or 250-0-250 kg are supplied with a set of self-aligning spherical rod-end connectors for tension loading. Force is applied to connectors through a hardened steel pin which must be slip fit in connector holes. 2,500-0-2,500 lb and 1,000-0-1,000 kg capacity gauges are equipped with two shackle adapters, shackles and pins. Shackles must be removed when compression load is involved. Force is then applied against shackle pins in a suitable test setup. All push-pull gauges are supplied with a compression-loading spherical ball fitting for compression loading.

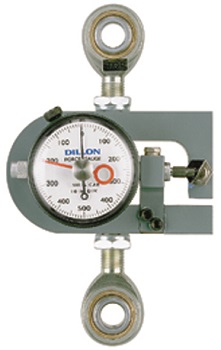

Dillon offers the Model X-ST in seven capacities from 100 lb to 10,000 lb or 25 kg to 5,000 kg. Accuracy is ±1% of full range. (Note: For applications requiring capacities beyond 10,000 lb or 5,000 kg in tension, consider the Dillon Dynamometer). Tension Force Gauges in capacities through 2,000 lb (1,000 kg) are supplied with two rod-end connectors. 5,000 and 10,000 lb (5,000 kg) capacities are equipped with convenient shackles and pins. Calibration is available in pounds and kilograms.

The Dillon Quick Check-T tension meter makes a difference. It reduces time on the job site by eliminating the need for whiteboards, changing sheaves, and the need for charts to figure out target tensions. This unit also reduces time off of the job site by having automatic site form completion, with image, and direct complete reports.

The Dillon Quick-Check tension meter is the premier innovation in the cable tensioning industry. Nothing comes close to the absolute simplicity of design and accuracy. It is ideal for cable guardrails, guy lines and overhead wires. The digital load cell is rugged, highly repeatable and accurate. The Dillon Quick-Check tension meter can be placed on a cable, measure its tension, and removed in under five seconds. There are no complex lookup tables or conversion charts – saving time and money. The Quick-Check tension meter can be employed in many industries requiring proper and provable tensioning. The operator can quickly select from 20 pre-calibrated wire sizes and types stored in Quick-Check’s memory. The Quick-Check tensioning mode graphically displays the current and target tension control limits for extremely quick setting of line tension. Even the infrequent battery changes are quick.